APRIL 4, 2023 | MHE OR FORKLIFT AND PEDESTRIAN SAFETY SYSTEM, USE CASES, COLLISION AVOIDANCE, COST REDUCTION

MHE (Material Handling Equipment) and forklifts are commonly used in a wide range of industries, from warehousing and manufacturing to construction and retail. While these machines are essential for efficient material handling, they also pose a significant risk to pedestrian safety in the workplace. In fact, according to OSHA, forklifts are one of the most frequently cited workplace hazards, and pedestrian accidents involving forklifts can result in serious injury or even death.

To mitigate this risk, many companies are investing in MHE and forklift pedestrian safety systems, such as IoT sensors, alarms, and cameras. These systems are designed to alert forklift operators when pedestrians are nearby and help prevent collisions.

But the benefits of these safety systems go beyond just avoiding accidents. By implementing these systems, companies can also increase productivity by reducing downtime caused by accidents, lower insurance costs by improving safety records, and improve employee morale by creating a safer work environment.

The diverse use cases for MHE and forklift pedestrian safety systems:

Use Case 1: Warehouse Operations

In warehouses and distribution centers, MHEs or forklifts are used to transport heavy goods from one location to another. However, with pedestrians working alongside MHE or forklifts, the risk of accidents is high. To address this, safety systems such as warning lights and audible alarms can be installed on forklift to alert pedestrians of their presence. Additionally, IoT sensors can be placed at intersections and blind spots to detect pedestrians and activate warning signals on forklifts.

Use Case 2: Manufacturing Plants

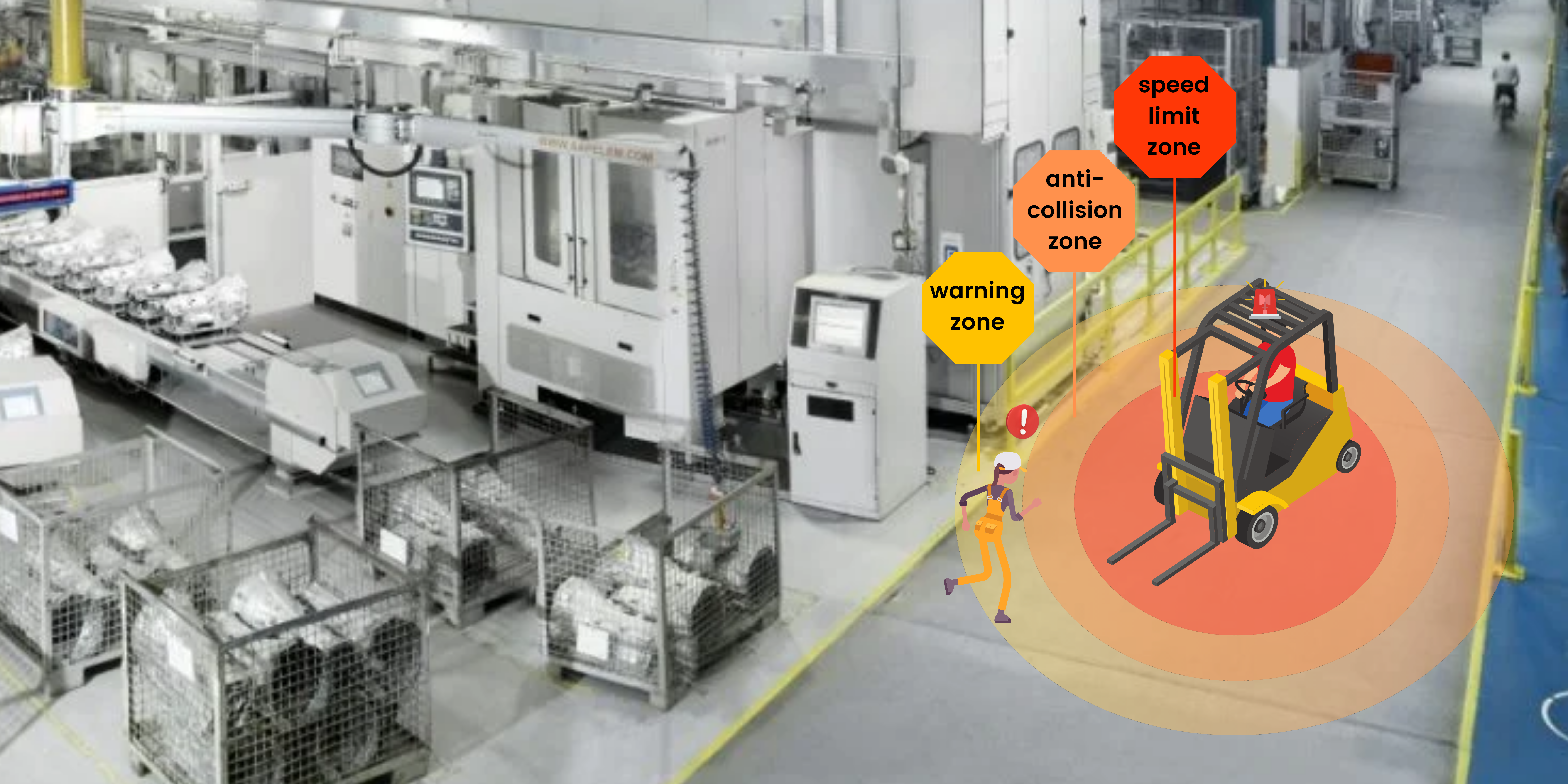

In manufacturing plants, problems such as the risk of collision between MHEs or forklifts and operators, frequent speeding, and falling items occur from time to time.

To avoid collision, the manufacturer installed the AI anti-collision warning system with a display screen to monitor pedestrians moving back and forth. Hence, the system automatically sends warning signals to MHE or forklift operators and pedestrians.

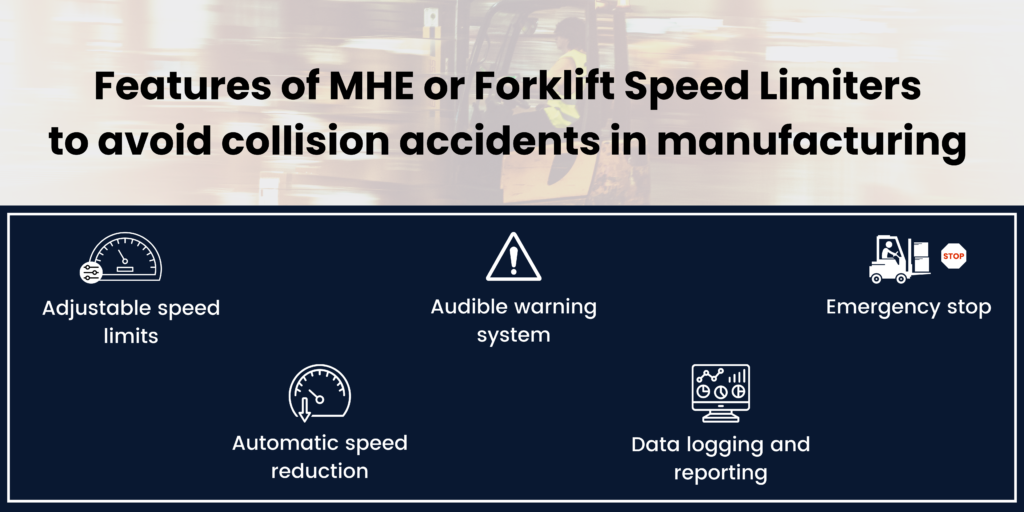

In addition, MHE or forklift speed limiter can be equipped to provide some useful features to increase safety of drivers and pedestrians as well as improve driving behavior.

- Adjustable speed limits: The speed limit can be changed depending on the requirements of the particular task or the operating environment.

- Audible warning system: Warns the operator and workers of MHE or forklift’s existence, especially when it is turning or going backward.

- Automatic speed reduction: Reduce the MHE or forklift’s speed automatically whenever it approaches an intersection or a walkway for pedestrians.

- Emergency stop: In an accident or when a collision is about to occur, the MHE or forklift must be stopped immediately.

- Data logging and reporting: Gather and report information about the MHE or forklift’s speed and movements so that it can be used to locate high-risk locations and enhance safety procedures.

Use Case 3: Retail Stores

Retail stores are considered one of the industries that are also equipped with MHEs or forklifts to move merchandise and products. Since the retail store is public, there will be many shoppers. It raises the danger of collisions with customers.

To minimize the risk of collision, the safety systems which are used in retail stores, include warning signs and barriers. Hence, forklifts and pedestrians can be separated by barriers, meanwhile the customers can be warned by warning signs when MHEs or forklifts are nearby. Additionally, MHEs or forklifts can have speed limiters added to lower the speed, which can significantly reduce the likelihood of collisions and injuries.

Use Case 4: Construction Sites

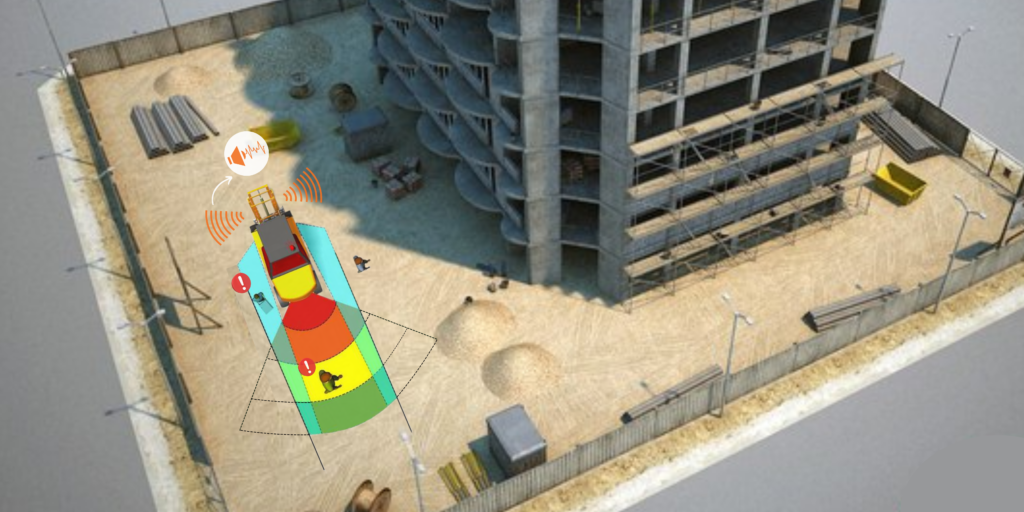

Another industry that usually adopts the MHEs or forklifts is construction sites to move the heavy materials such as concrete, steels, bricks, and others efficiently. However, the limited space makes it difficult for workers and MHEs or forklifts to move around, particularly since workplaces are frequently busy and chaotic. As a result, collision accidents occur because the MHE or forklift operators are unable to see the workers clearly.

To solve such problems, construction sites apply the combination of cameras and sensors that offer a 360-degree viewing capabilities as a security system for MHEs or forklifts. Thus, the camera provides a clear view of the work area where there is poor visibility or blind spots. Besides, the system also assists in detecting pedestrian surroundings and notify MHE or forklift users of potential dangers. It prevents equipment damage and worker injury.

Conclusion

In conclusion, MHE and forklift pedestrian safety systems are critical for protecting workers and preventing accidents in a variety of industries. By implementing these systems, companies can improve safety records, increase productivity, and create a safer work environment for their employees.