JULY 28, 2025 | MAXIMUM DEMAND MANAGEMENT, ENERGY OPTIMIZATION AND MONITORING, ESG, SUSTAINABILITY, EFFICIENCY

Starting 1 July 2025, Tenaga Nasional Berhad (TNB) revised its Maximum Demand (MD) charges for medium-voltage non-domestic customers under the Time-of-Use (TOU) scheme to RM97/kW. While this might seem like just another tariff change, the reality is more urgent: just one unexpected 30-minute power spike during peak hours (2pm – 10pm) can cost your business thousands of ringgit.

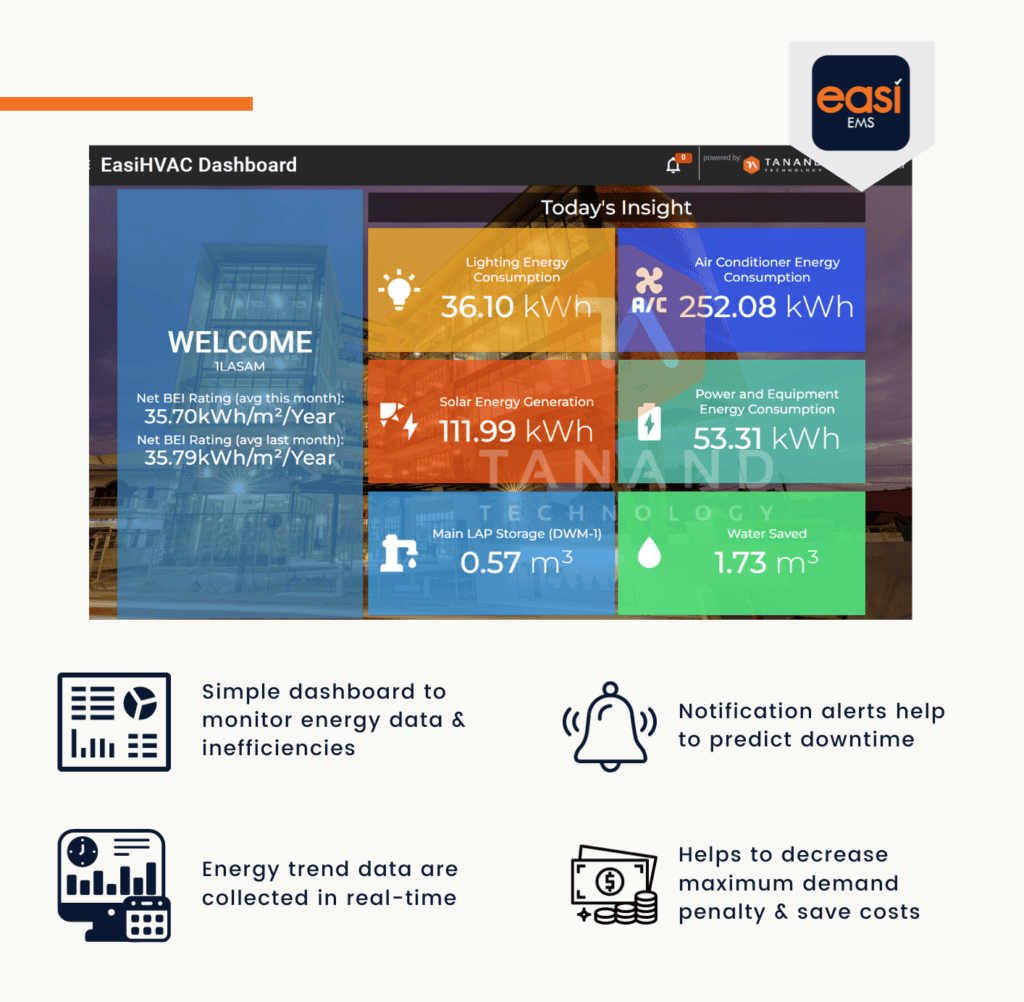

That’s where EasiEMS comes in. Our Smart Peak Demand Control system empowers you with real-time visibility, predictive alerts, and control — all aimed at helping you avoid costly MD penalties.

Why TNB Maximum Demand (MD) Charges Matter

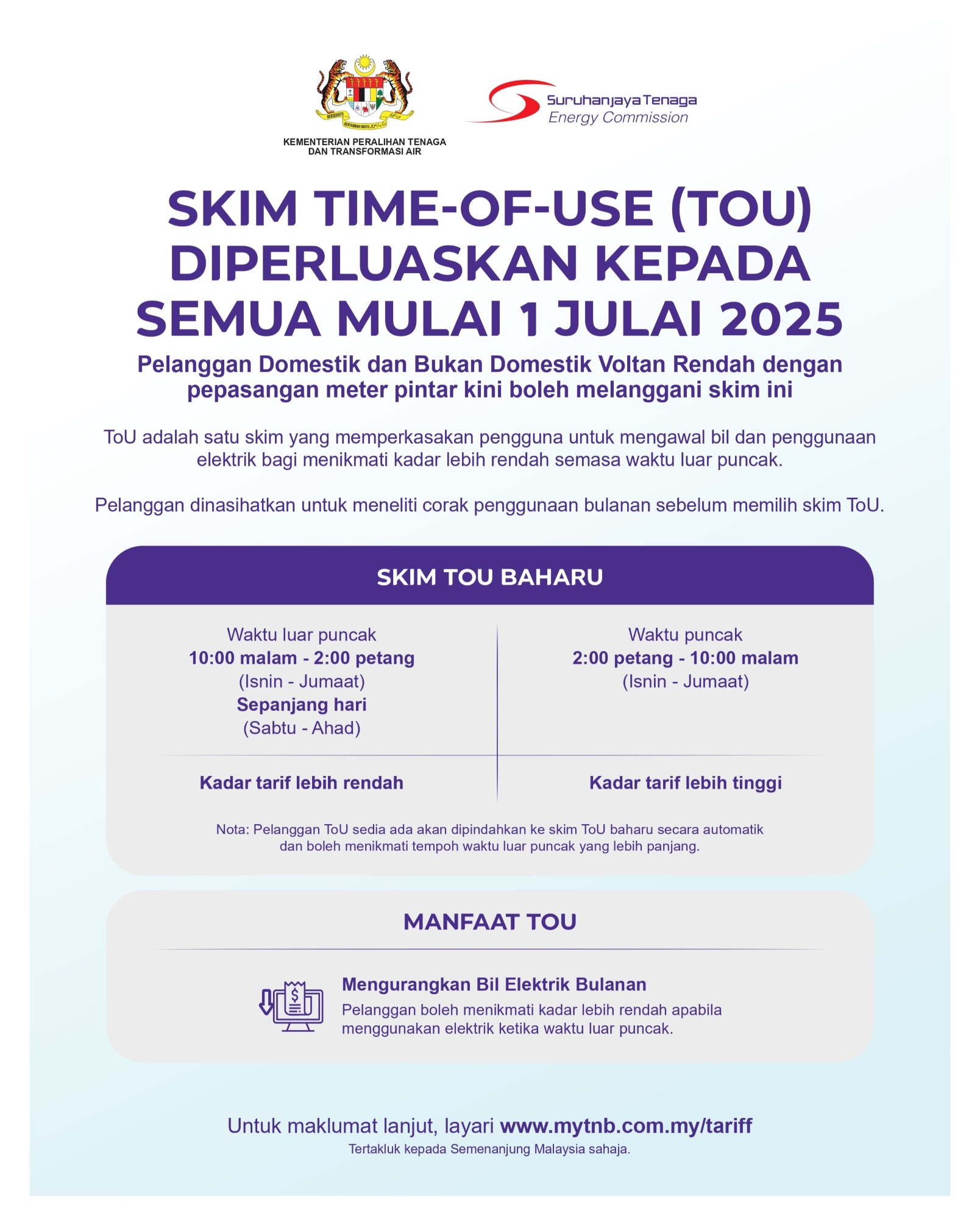

Under TNB’s TOU scheme:

- Peak Hours: 2:00 PM – 10:00 PM (Monday to Friday)

- Off-Peak Hours: 10:00 PM – 2:00 PM (including weekends and holidays)

Your MD is calculated based on the highest 30-minute average kW usage during these peak hours. With the new charge of RM97.06/kW (RM30.19 for Capacity + RM66.87 for Network), this adds up quickly — especially for energy-intensive industries.

Even a brief spike in demand can lock you into a higher monthly MD charge, even if your average consumption is low.

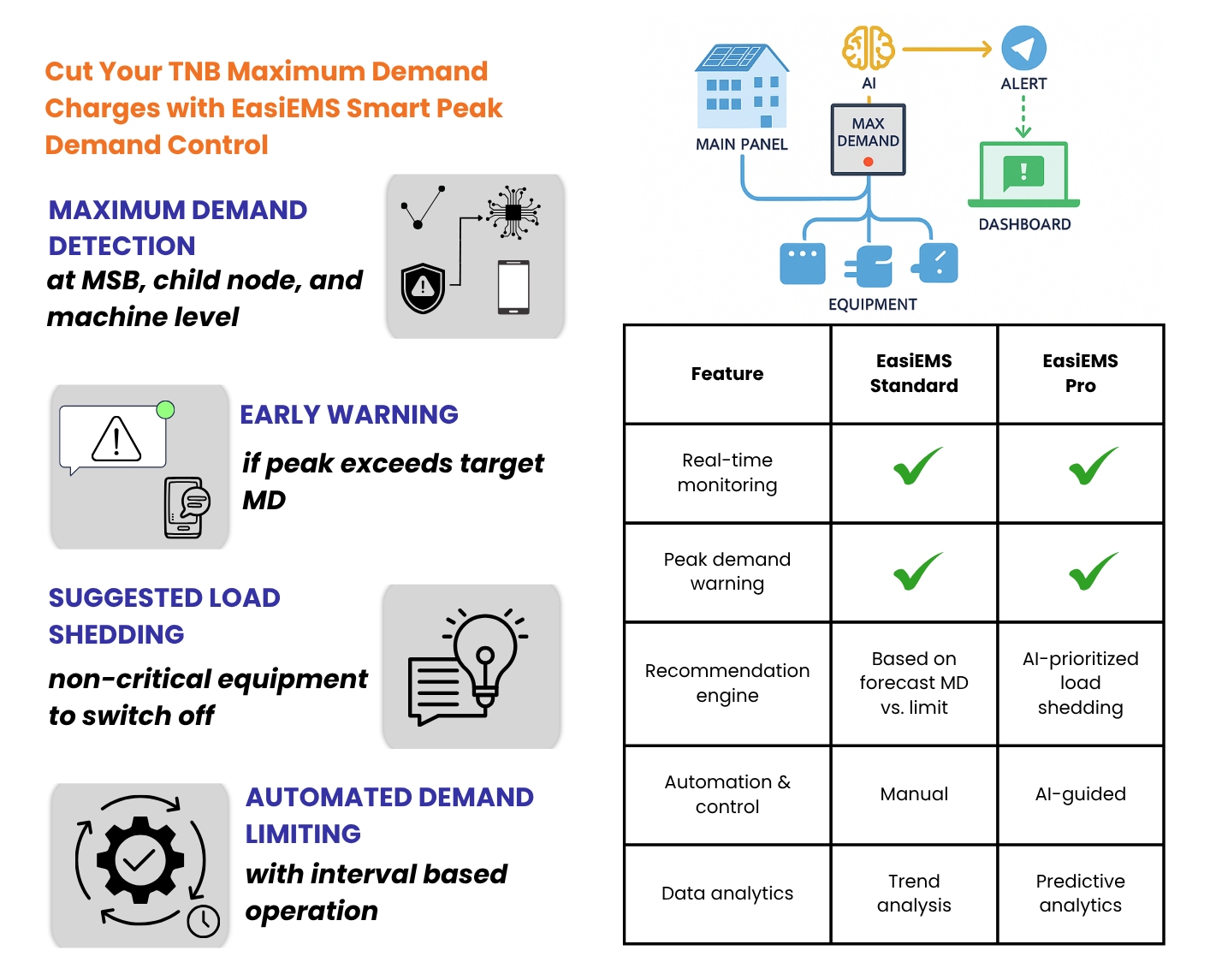

Meet EasiEMS – Granular MD detection (Beyond MSB Level)

EasiEMS is designed to provide insight and control at every level:

- Main Switch Board (MSB) Level– Real-time monitoring aligned with TNB’s 30 mins MD calculation

- Child Node Level – Pinpoint which distribution boards cause peak demand

- Machine Level– Identify the exact equipment contributing to MD spikes

Early Maximum Demand Warning System – Stop MD Before It Happens

EasiEMS continuously calculates your 30-minute running average demand, just like TNB’s meter.

Example Scenario:

- Target MD Limit: 800 kW

- Current Average at 2:15 PM: 750 kW -> early warning triggered

- Projected 30-Minute Peak: 810 kW (if no action taken)

At this point, EasiEMS triggers an Early Warning via Telegram/WhatsApp, Email, or the Mobile App, with recommendations on what actions to take — before an MD breach happens.

Smart Load-Shedding – Automated Recommendations in Real Time

EasiEMS goes beyond alerts. It recommends exact actions based on equipment type, runtime, and load priority.

| Equipment | Rated Demand (kW) | Suggested Action |

|---|---|---|

| AHU 3 (Office Zone B) | 25 | Switch off for 30 minutes |

| Air Compressor 2 | 45 | Delay operation for 15 minutes |

| Chiller 2 | 90 | Temporarily reduce setpoint/cycle-off |

| Production Line C Fan 5 | 10 | Switch off for 15 minutes |

Automated Demand Limiting Control

For key equipment connected to the Max Demand Limiting Controller, EasiEMS enables:

🖥 Remote Switching – One-click OFF from the dashboard

🤖 Auto-Control Mode – Auto switch-off for 15 or 30-minute intervals on selected loads

This ensures immediate action, even when staff can’t respond fast enough.

Case Study Simulation – What You Can Save

By strategically reducing MD, you could save tens to hundreds of thousands of ringgit annually:

| MD Reduction (kW) | TOU MD Charge (RM97/kW) |

Monthly Saving (RM) | Annual Saving (RM) |

|---|---|---|---|

| 20 | RM1,940 | RM1,940 | RM23,280 |

| 50 | RM4,850 | RM4,850 | RM58,200 |

| 100 | RM9,700 | RM9,700 | RM116,400 |

| 200 | RM19,400 | RM19,400 | RM232,800 |

Case Study Simulation – Before vs After EasiEMS Implementation

A semiconductor plant previously recorded an MD of 2550 kW during peak hours, resulting in a monthly MD charge of RM82,501 (850 kW × RM97.06). After installing EasiEMS, the plant successfully reduced its peak demand to 2450 kW by automatically cycling off two air compressors and rescheduling non-critical AHUs during the 2 PM to 10 PM TOU window.

This 100 kW reduction translated to a direct monthly saving of RM9,706 and an annual saving of RM116,472. Additionally, by reviewing machine-level MD data, the plant optimized chiller operations, achieving further energy savings beyond the MD cost reduction.

Before vs After EasiEMS – MD Cost Comparison

| Item | Before EasiEMS | After EasiEMS |

|---|---|---|

| Maximum Demand (kW) | 2550 kW | 2450 kW |

| MD Charge Rate (TOU) | RM97.06/kW | RM97.06/kW |

| Monthly MD Charge | 2550 × RM97.06 = RM82,501 | 2450 × RM97.06 = RM77,648 |

| Monthly Saving | – | RM9,706.00 |

| Annual Saving | – | RM116,472.00 |

Based on non-domestic medium voltage with ToU, Max demand charges (during peak hours):

Capacity Charge: RM30.19/kW + Network Charge: RM66.87/kW = RM97.06/kW

ToU scheme has 2 time zones (Peak and Off-Peak):

- Monday to Friday: Peak: 2:00pm to 10:00pm

Off-Peak: 10:00pm to 2:00pm - Saturday, Sunday and Public Holidays*:

Off-Peak all day (24 hours) ← Lower Footer

MD is measured in Kilowatt (kW). MD is the highest level of electricity demand recorded by TNB meter during a 30-minute interval in a month that occurs during peak period.

The kW amount charged to customers is based on Recorded MD (kW) x *MD Charge Rate

| Non-Domestic Medium Voltage ToU Tariff | ||

|---|---|---|

|

Energy Charge For all kWh during the peak period |

sen/kWh | 31.32 |

|

Energy Charge For all kWh during the off-peak period |

sen/kWh | 27.23 |

|

Capacity Charge For each kilowatt of maximum demand per month during the peak period |

RM/kW | 30.19 |

|

Network Charge For each kilowatt of maximum demand per month during the peak period |

RM/kW | 66.87 |

| Retail Charge | RM/month | 200.00 |

Source: https://www.mytnb.com.my/tariff/index.html?v=1.1.29

EasiEMS Smart Peak Demand Control

Conclusion – Lower Your Energy Bills Without Sacrificing Operations

When just 30 minutes of high usage can cost you thousands, you need more than manual monitoring. EasiEMS makes energy-saving automatic and stress-free.

With smart alerts, equipment-level insights, and built-in load control, you can reduce Maximum Demand charges while improving overall energy efficiency — without affecting daily operations.

Whether you’re managing a factory, commercial building, or industrial site, EasiEMS gives you the visibility and control to save money every month.

Let us show you how much you could be saving. Reach out to our team to assess your eligibility and project fit at our contact page to speak with our technical experts.

Frequently Asked Questions

Maximum demand shedding is a strategy to reduce electrical costs by temporarily reducing or turning off non-essential loads during peak demand periods, preventing the maximum demand charge from exceeding a set target. This is often managed by a Maximum Demand Controller (MDC) that monitors electrical usage and automatically sheds loads based on pre-set parameters.

The MDC continuously monitors the electrical load and the time interval (e.g., 30-minute period).

If the monitored load approaches the pre-set maximum demand limit, the MDC automatically sheds specific loads, usually non-essential ones.

This shedding can involve turning off equipment, reducing the speed of motors, or switching to alternative cooling methods.

The goal is to bring the demand back below the threshold before the end of the interval, avoiding the higher maximum demand charge.

Real-time Monitoring:

MDCs continuously monitor electricity consumption, typically in 15, 30, or 60-minute intervals.

Setting Demand Limits:

Users define a maximum demand limit, which the MDC aims to stay below.

Predictive Algorithms:

Many MDCs use algorithms to forecast future demand based on current usage patterns and adjust load shedding accordingly.

Load Shedding:

If the MDC predicts that the demand will exceed the set limit, it automatically sheds or reduces the power to non-critical loads, such as lighting, air conditioning, or specific machinery.

Load Cycling:

Some MDCs can also implement load cycling, where non-essential loads are temporarily turned on and off in a controlled manner to manage demand.

Preventive Measures:

By forecasting potential peak demand, MDCs can proactively initiate load shedding to avoid exceeding the limit, minimizing disruptions to critical operations. Example Scenarios –

Industrial Examples:

Manufacturing facilities might temporarily shut down non-essential machinery, like certain production lines or conveyor belts, during peak hours.

Commercial Examples:

Office buildings might adjust thermostat settings, dim lights, or shut down non-essential equipment during peak hours.

Maximum Demand (MD) refers to the highest 30-minute average electricity usage recorded during peak hours in a month. TNB calculates this during the 2:00 PM to 10:00 PM peak period on weekdays, and charges customers based on the highest kW demand reached.

As of 1 July 2025, TNB charges RM97.06 per kilowatt (kW) for MD under the Time-of-Use (TOU) scheme for medium-voltage non-domestic customers. This includes a Capacity Charge of RM30.19/kW and a Network Charge of RM66.87/kW.

A single half-hour spike during peak hours can lock you into a higher MD charge for the entire month, potentially costing your business thousands of ringgit.

Managing MD helps avoid this and reduces your electricity bill significantly.

EasiEMS helps you track, manage, and control your energy usage in real time. It offers machine-level insights, sends early warning alerts, and recommends or automates load-shedding actions to prevent demand from exceeding your set limits.

EasiEMS provides early MD breach alerts through Telegram, WhatsApp, email, or the mobile app. These alerts include demand forecasts and actionable suggestions on which loads to reduce or switch off.

Yes. For equipment connected to the Max Demand Limiting Controller, EasiEMS can either remotely switch off selected loads or automatically do so at preset thresholds using its Auto-Control Mode.

By reducing your MD by just 20 to 200 kW, you can save anywhere from RM23,280 to RM232,800 annually. For example, reducing 50 kW in peak demand saves you RM4,850 every month.