- Solution NextGen T-EMS

- Year Deployed 2021

- Location Shah Alam, Selangor

- Industry Semiconductor manufacturing

Business Situations

Founded in 1988, Shin-Etsu Polymer (Malaysia) Sdn Bhd is a leading manufacturing company mainly focusing on PVC and semiconductor silicone products. Due to its high maximum demand, the company faced an unmanageable high energy bill.

Common utilities such as air chillers, air compressors, air-cooled compressors and other equipment are installed with a shared control panel, making it difficult to detect which department or equipment that contributed to the maximum demand charges. They have more than 100 product types and are unable to track energy cost for each product on a detailed level.

Hence, the company looked for an energy monitoring and a predictive maintenance solutions which would allow them to monitor all of the issues mentioned above.

The Challenges

Solutions & Results

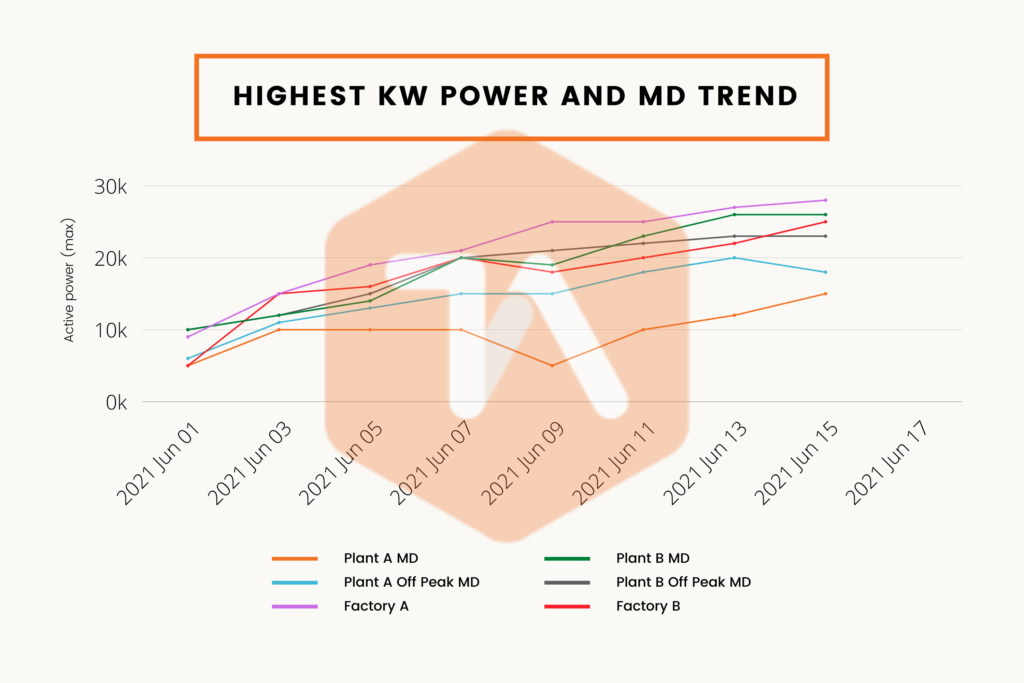

In order to solve the issues, the Tanand Energy Monitoring System (NextGen T-EMS) was implemented to measure and monitor approximately 35,000A (10MW) for more than 200 smart energy metering points in real-time basis.

This customized IIoT solution provides real-time analytics, and is utilized daily by stakeholders such as plant managers to monitor data and extract production reports for further improvements.

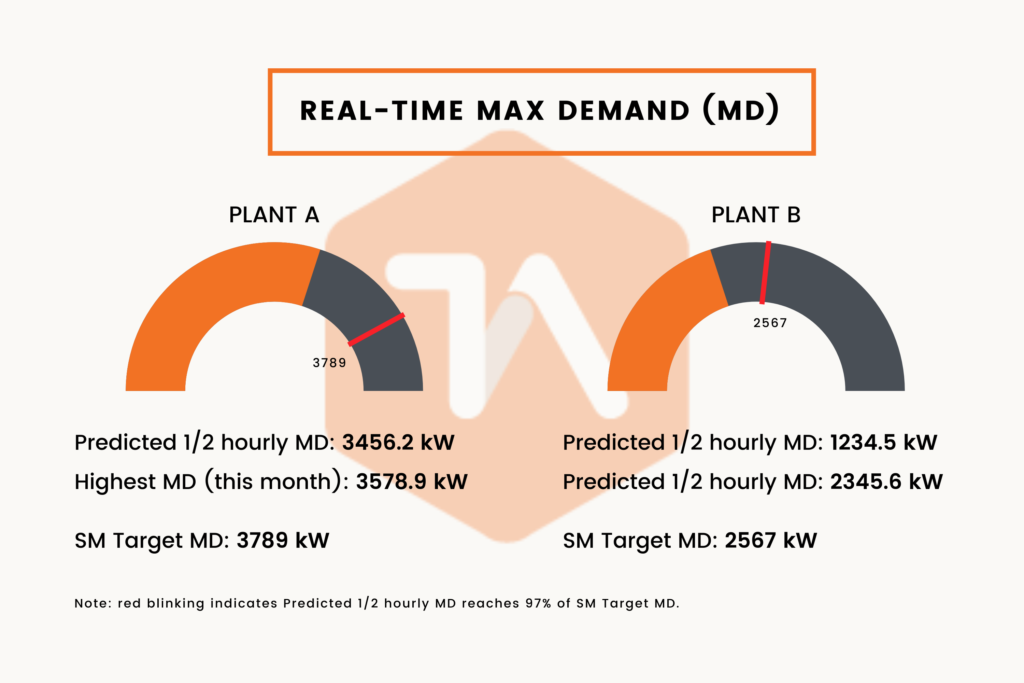

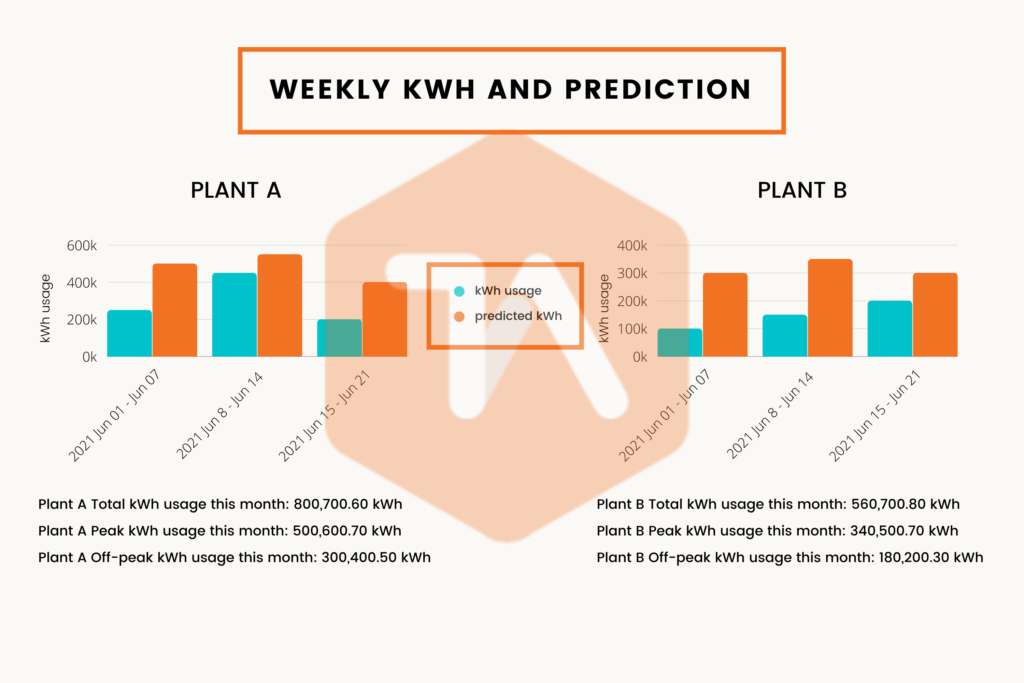

There is also customizable interfaces and logics that provide real-time maximum demand prediction and detailed energy consumption based on product categories, equipment and areas, such as chillers, air compressors, air-cooled compressors, lighting and canteen spaces. By monitoring the real-time energy utilization pattern, Tanand’s NextGen T-EMS is also able to provide instant notifications in Whatsapp/Telegram for any abnormalities occurring at the production floor.

Benefits

Enable 24/7 real-time energy monitoring and usage visibility.

Able to forecast maximum demand in real-time basis.

Smart energy meter that provides in-depth analytics and detailed insights on energy cost by product or department.

Provide instant notification in WhatsApp/Telegram.

The Tanand Energy Monitoring System (NextGen T-EMS) has provided significant help to our company in monitoring and forecast our maximum demand in real-time basis, as well as keep track of detailed energy cost by products. We can also utilize their system for the predictive maintenance of common utilities such as air compressors and chillers.

— Shin-Etsu Polymer (Malaysia) Sdn. Bhd.