JULY 10, 2021 | CLEANROOM TECHNOLOGY, PREDICTIVE CONDITION MONITORING, HVAC ENERGY SAVING INSIGHTS

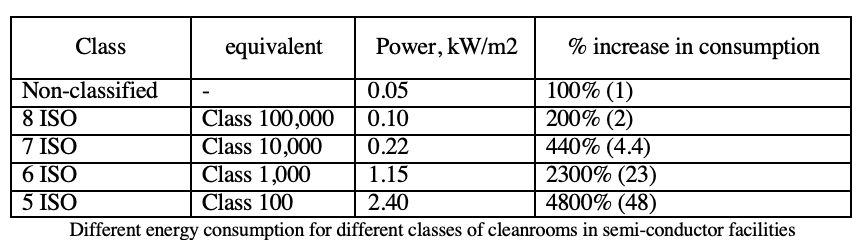

Cleanrooms requires high energy usage, and it’s typical for power requirements to be specified based on standards rather than a thorough grasp of the dynamics. Cleanrooms require a significant amount of energy – ranging from 2 to 50 times that of non-classified spaces, depending on the application.

Despite knowing that, it is challenging to achieve energy savings in cleanrooms because of the stringent conditions they adhere to, such as maintaining a temperature control limit of below 26°C, a humidity control limit of below 60%, additional positive pressure in the sealed area and so on.

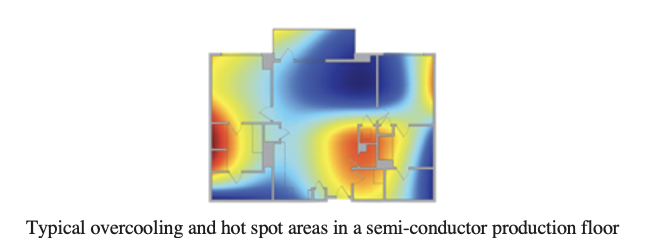

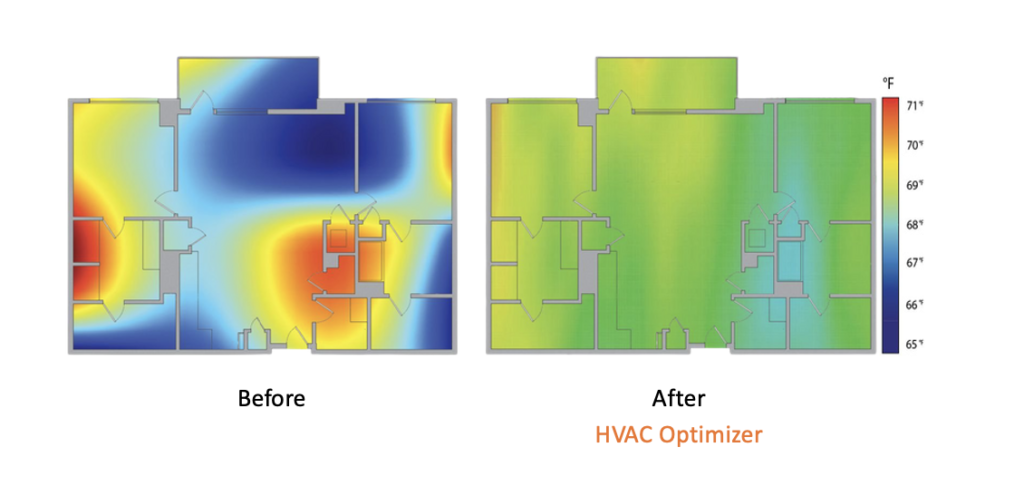

With overcooling as the only method to maintain the temperature control limit for a cleanroom, not only it is producing energy wastage, air balancing issues and hot spot areas are also hard to identify due to the limited availability of sensors (typically 1 sensor per 5k-10k sqft) on the production floor of a semiconductor manufacturing plant.

Not to mention that measuring dust particulate concentration is normally performed via manual sampling method and not on a real-time basis, such reactive and corrective measurements would have already caused defects to products, easily wasting millions in value during just a single shift.

Higher Feedback Accuracy with Real-Time Sensors to Maximize Cleanroom Energy Savings and Minimize Product Defects

Tanand places various real-time wireless sensors throughout the production floor to automate energy consumption and prevent air contamination through heat-load balancing and indoor sensors.

- Our non-invasive temperature, humidity and pressure sensors can be easily clipped-on via Velcro patch without complicated and dusty wiring works that will cause cleanroom operation downtime.

- Our sensors can be linked to your Wifi network, Power over Ethernet (PoE) and LoRa, which will then be able to work independently without the need to upgrade your existing cleanroom infrastructure.

- Although our sensors can run purely on Lithium battery (1-2 years of lifespan with a single charge), they can be also be powered up by any 5Vdc power source in the cleanroom through a micro-USB.

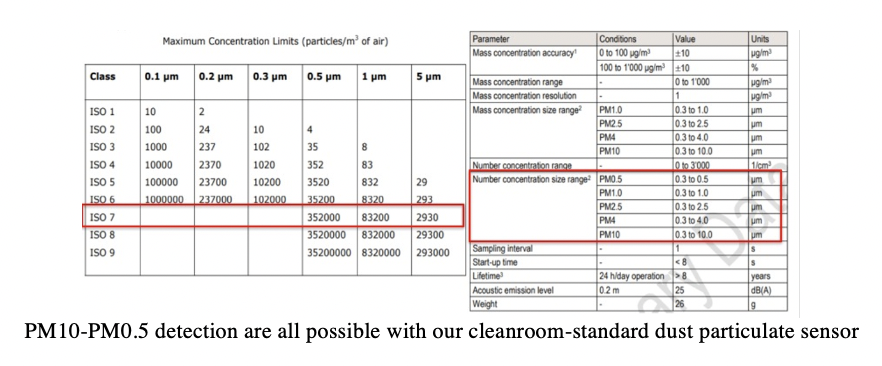

- Our cleanroom-standard dust particulate sensors can detect PM0.5 air in real-time using optical sensing method.

A Smart HVAC Solution That Is Beyond Temperature Control

- Dynamic air side balancing with real-time demand control algorithm.

- Dynamic chilled water balancing with real-time chiller set point & part load optimization.

- Access to various inputs such as heat loads, humidity, zone-specific temperatures, airflow temperatures, weather, occupancy and so on.

- Instant alert via Telegram or WhatsApp when operating control limits thresholds (e.g. temperature, humidity, pressure, dust particulate) are exceeded.

- Save installation cost, implement fast and reap significant savings!

Improving Chiller Lifespan with Predictive Condition Monitoring

Chiller is not only the most important workhorse, but also the most expensive asset in a building. Hence, chiller can easily be the biggest power consuming equipment in your cleanroom.

With the unique features of EasiChiller:

- Prolong your chiller lifespan with predictive conditioning monitoring specifically designed for chiller

- Powered with IoT sensors (energy, noise, vibration, flow/delta T) for real-time scanning and machine learning fault analysis through your chiller logs (EasiChiller+)

- A Data-Driven Chiller Expert to monitor your critical chiller 24×7 with trend analysis

- Monthly summary report for your chiller health score & historical scoring trend via email to never miss any insights

- Instant notifications for your operation team via Telegram or WhatsApp to detect potential faults and major damages before they occur

- Analyze & audit the performance or health score of your chiller after every maintenance job

Easily achieve the benefits:

- Save energy – Chiller performance will be closely monitored to ensure energy efficiency

- Reduce workload issues – Avoid under-maintenance that causes unpredicted chiller breakdowns & over- maintenance that causes unnecessary chiller or spare parts replacements

- Increase chiller lifespan – While a normal chiller lifespan is around 15-20 years, a well-maintained chiller with predictive condition monitoring can easily operate up to 25 years. That additional lifespan of 5 years in your chiller with a capital expenditure of RM500,000 will save you RM125,000.00 – RM166,667.00.