- Solution EasiHVAC (HVAC Optimizer)

- Year Deployed 2025

- Location Negeri Sembilan / Melaka

- Industry Semiconductor Manufacturing

Introduction

Onsemi (ON Semiconductor Malaysia) and Infineon Technologies Malaysia—two major players in the industry—sought a way to reduce HVAC energy costs while preserving cleanroom compliance and process stability in semiconductor production.

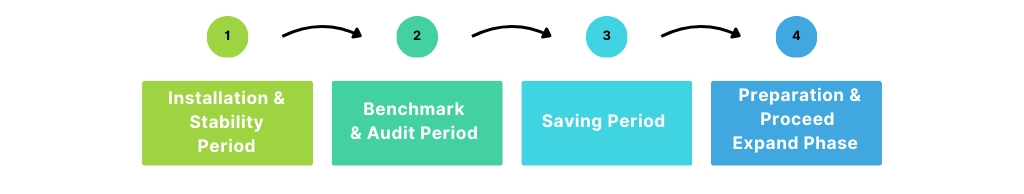

Tanand Technology successfully deployed its EasiHVAC Adaptive Air-Side (AHU) Energy Optimisation system at two major semiconductor manufacturing facilities. Both projects were executed as Proof-of-Concepts (POCs) to demonstrate real-time AIoT-enabled energy savings and environmental performance improvements through smart Air Handling Unit (AHU) optimisation.

Project Highlight 1: Onsemi Malaysia – Plant 1, Seremban

Onsemi required a more adaptable control strategy to maintain cleanroom precision while improving energy efficiency across different production scenarios. The challenge was to reduce energy usage while maintaining cleanroom air parameters across multiple AHUs.

What Tanand Delivered

Energy Saving Achieved

- Energy saving up to 40%

- Maintained 32.5%–35.9% savings across POC months, even during hotter and more humid conditions

Outcome

- POC successfully validated and extended to the next phase involving more AHUs unit

AI vs. Manual Control

- AHUs in auto-mode significantly outperformed those that were manually overridden– showcasing the effectiveness of AI-based optimisation compared to manual override that are lower in efficiency

Project Highlight 2: Infineon Technologies Malaysia – Block 10, Melaka

Infineon required a more adaptable control strategy to improve it’s Block 10’s energy efficiency while maintaining the same human comfort across different areas in the buildings.

What Tanand Delivered

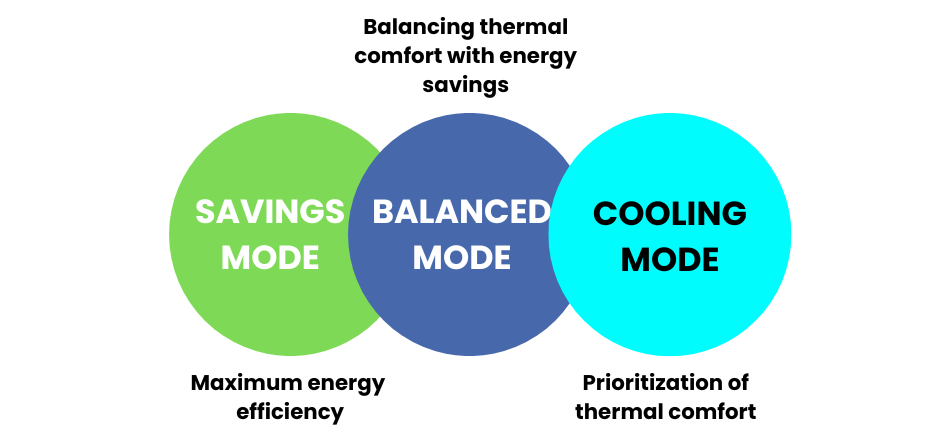

Deployment of multi-mode AHU Advanced Control

- Savings Mode – Maximum energy efficiency

- Balanced Mode – balancing thermal comfort with energy savings

- Cooling Mode – prioritization of thermal comfort

Smart Sensor Integration

- Temperature & Humidity

- CO₂

- Human Occupancy

Custom Features Implemented

- QR Code Feedback System

- Customisable Set Point Logics

System Integration:

- Evaluated for Niagara-based BMS compatibility

Result & Impact

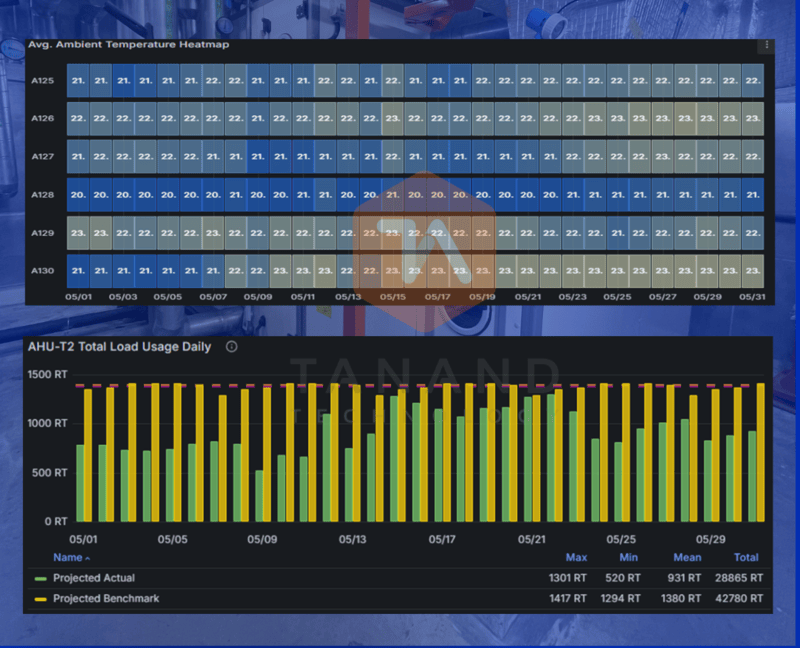

- Demonstrated automated air-side optimisation with real-time monitoring, analytics, and intelligent fan/valve control

- Enabled digital transformation for HVAC systems at scale with measurable results

- Supported client’s ESG and sustainability goals through energy efficiency and CO₂ footprint reduction

Conclusion

These successful implementations at ON Semiconductor and Infineon Technologies underscore Tanand Technology’s proven expertise in delivering real, data-driven HVAC energy optimisation in challenging industrial settings.

With POC validations and permanent deployments completed, EasiHVAC stands out as a robust, scalable, and intelligent air-side optimisation platform for large-scale energy-conscious operations in the semiconductor industry.